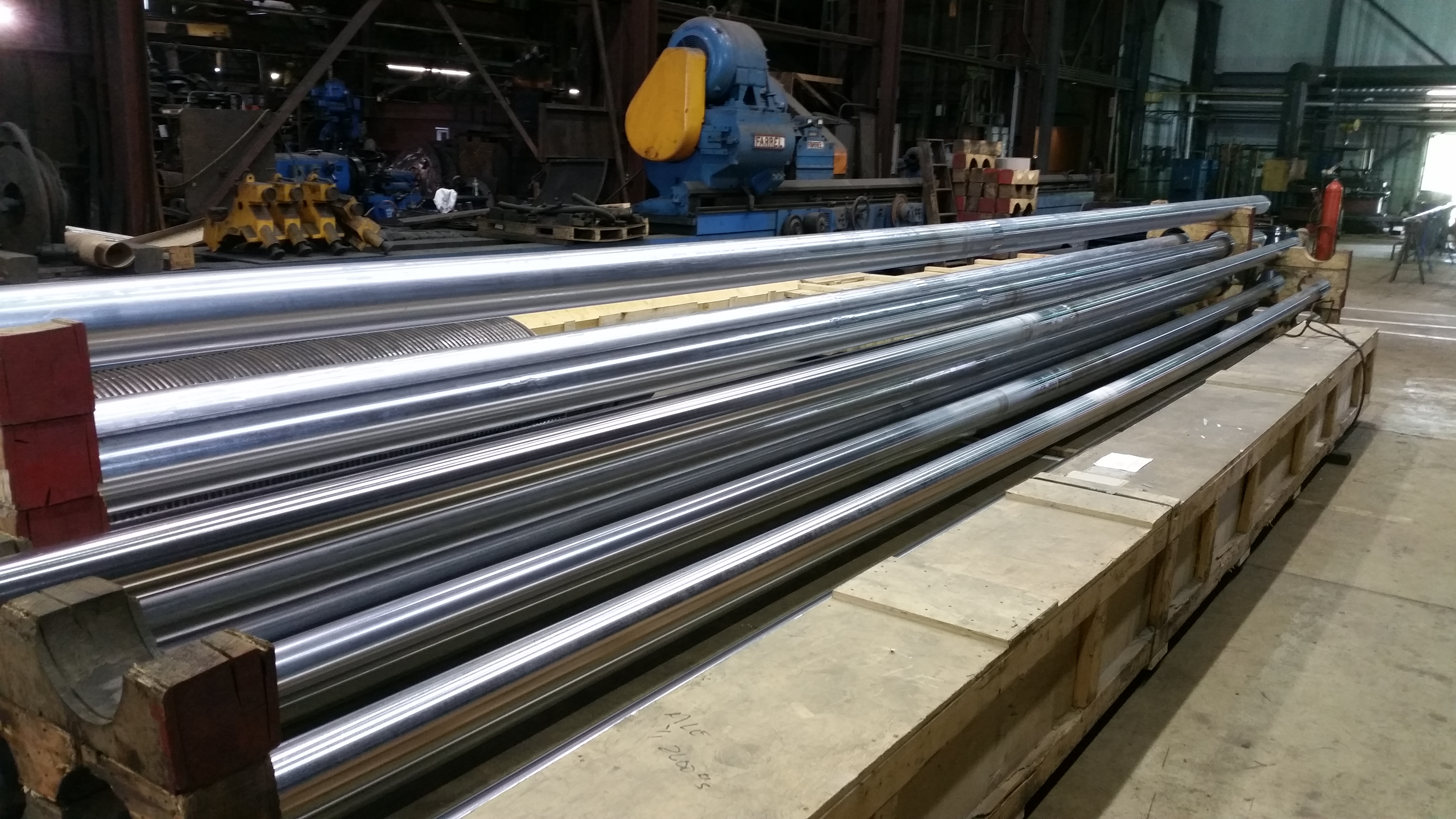

At Youngstown Hard Chrome, we hard chrome plate and polish the mandrel bars highlighted here, which are used in the manufacture of seamless tubing. They measure from 6” to 13” in diameter x 528” in length. We process six of these mandrel bars on a daily basis for a company in the local area.

Problem:

The oversized proportions and massive weight of these workpieces required special handling to maneuver them through the plating line and onto the polishing equipment. In addition, we had to process the mandrel bars in an expedited manner to meet the customer’s delivery schedule to avoid production outages at their plant.

Solution:

To address the difficulty of handling these large and heavy mandrel bars, we installed two 15-ton capacity overhead hoist cranes. We also situated two 35’ long plating tanks to accommodate the workpieces and then equipped the tanks with eight new plating rectifiers. The powerful new rectifiers provided a controlled flow of low-ripple current over the long plating cycle time, which enabled an exceptionally wear-resistant and abrasion-resistant hard chrome finish to build up with uniform coverage and density. With our large capability polishing equipment, we finished the workpieces entirely in-house.

Results:

By accumulating a variety of quality metrics, we confirmed that the plated and polished surface finish met the client specifications. Along with visual inspection, we profiled the surface to ensure there were no cracks, pinholes, or other defects and used a high-resolution digital tester to measure the thickness buildup of the hard chrome plating. Our efficient process methods kept production costs very reasonable and we received extremely complimentary feedback from the customer on the quality of the hard chrome finish.

Contact us today if you are interested in learning more about our hard chrome process capabilities.

Tubing Mandrel Bar Highlights

- Project Name & Description

- Mandrel Bars for Seamless Tubing

- Capabilities Applied/Processes

- Chrome Plating

Polishing

- Equipment Used to Manufacture Part

- Deep chrome plating tanks

Large Polishers

- Overall Part Dimensions

- OD: 6” Dia. / 13” Dia. x 528” Length

- Tightest Tolerances

- ±.001”

- Material Used

- Industrial Hard Chrome

- Material Finish

- Polish

- Industry for Use

- Gas

- In Process Testing/Inspection Performed

- Visual Inspection

Digital chrome thickness tester

Profilometer (Surface finish)

- Volume

- 6 per day

- Delivery/Turnaround Time

- 6 per day

- Delivery Location

- Ohio, USA

- Standards Met

- As per customer specifications