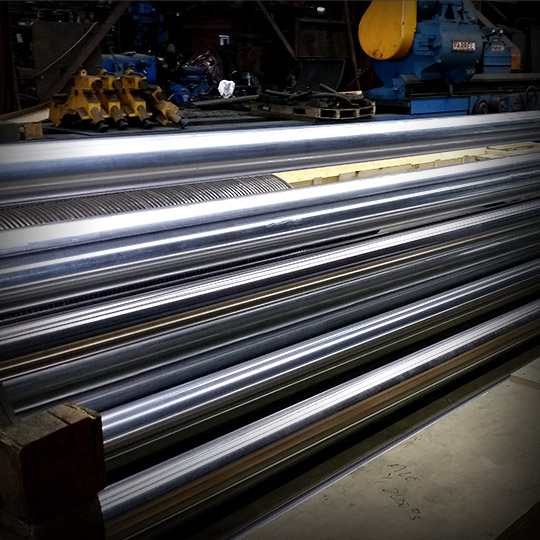

Hard chrome plating offers one of the most durable finishes for industrial applications, for this reason; there are many sources for this plating process. However, there are very few with the capacity for large-scale hard chrome plating that we offer at Youngstown Hard Chrome.

Hard chrome plating offers one of the most durable finishes for industrial applications, for this reason; there are many sources for this plating process. However, there are very few with the capacity for large-scale hard chrome plating that we offer at Youngstown Hard Chrome.

Our facility is equipped with eight plating tanks of varying sizes that can accommodate work pieces up to 102” in diameter and 720” in length. This is a precision process that can apply plating in thicknesses as thin as .0005”, with industry leading consistency. These plating systems utilize 80,000 amp DC rectifiers and are ideally suited to plate various grades of steel as well as high strength steel, stainless steel, brass, bronze, copper, and number of high nickel alloys.

As a leading provider of industrial hard chrome plating, with over half a century of experience, we understand well that the most hi-tech plating process means little if the parts are not properly prepared. For this reason, we also provide a full range of pre-plate processes, these include aluminum oxide sand blasting, caustic soda stripping, reverse etching, shot peening, and glass bead peening that is in full compliance with MIL-S-5002. After plating we can also provide precision grinding, honing, polishing, and super finishing that can impart finishes from 1 to 32 RMS. We can also reverse engineer plating to bring obsolete components back to OEM specification and provide complete QC documentation.

These capabilities combine to position us as a single source solution for hard chrome plating. To learn more about the benefits of working with an industry leader, see the table below or contact us directly.